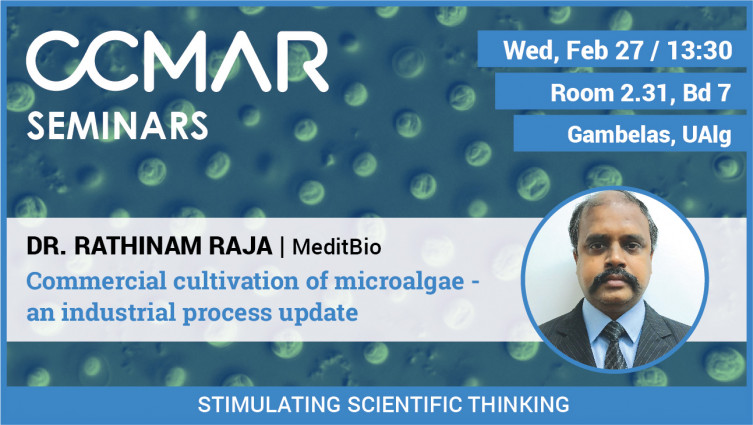

Commercial cultivation of microalgae-an industrial process update

Two types of Scenedesmus sp algal cultures were maintained in indoor open tanks of Aquatic Energy LLC, Lake Charles, Louisiana. The pH, temperature, contamination level, cell count, Chl a, b and OD were taken thrice a day to maintain healthy cultures. Due to water evaporation and rainfall (during summer and winter seasons) water levels were adjusted often. For example, on summer, pH were shoot-up in the morning, during that time CO2 were supplied directly to the ponds to bring down the culture pH normal along with fresh water. On winter due to rainfall, water levels have been increased, these water levels were calculated subsequently nutrients were added close to the paddle wheels (so that nutrients will be mixed thoroughly) to compensate the dilution of the nutrients especially on rainy seasons. N, P, K were used as nutrients to make the product (biomass) cost-effective.

About our speaker:

Dr. Rathinam Raja pursued his Masters (Plant Science) and Ph.D., (2004) at University of Madras on microalgae. He did his Post-Doctoral Fellowships at Taiwan, South Korea and IIT Madras. Couple of years, he has worked as a Lead Scientist at Aquatic Energy LLC, Louisiana, USA.

Since 2012, he worked as a Post-Doctor at Meditbio and recently joined as an Investigator under the direct supervision of Prof.Isabel S Carvalho’s lab. Currently, he is working on seaweeds on food science related area, he also serves as an Associate Editor, Editorial Board member and reviewer in many scientific international journals.

This seminar was kindly sponsored by: